Pada is proud to announce a new high efficiency heat sink. In fact, a new Pada copper heatsink is available to meet thermal requirements, in case of very high power to dissipate and /or concentrate in small powerful components. Pada SuperFin can be produced completely in copper (base and fins) or, for lower power, with aluminium fins.

R&D Pada laboratories have designed and developed a new and wide range of products named SuperFins. In order to solve the continuous increase of power in electronic devices, SuperFins fullfill all necessary parameters.

Pada’s SuperFins are able to reduce volume and/or dissipate the very high and concentrate power per unit. It doesn’t matter if we are talking about Broadcasting systems or Power Supply or UPS or any other electronics applications.

Always looking ahead to costs optimisation and flexibility of their systems, Pada SuperFins are properly designed to be produced according to the specific thermal customer’s needs.

1) Materials used are copper and/or aluminium alloy.

2) The standard finishing is a simple washing (degreasing).

3) The flatness of the components assembling surfaces is of 0,015 mm/200x200 mm, and the roughness Ra = 1.2 μm.

in length and in width

<= 500 mm +/- 0.5 mm

> 500 mm +/- 1 mm

in height

+/- 1mm

Dimensional tolerances:

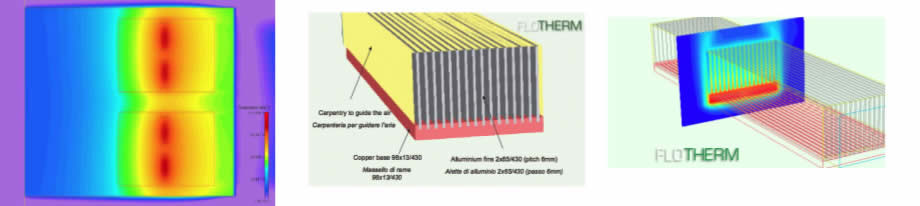

Pada SuperFins are made through combining different components: copper extruded or machined base and extruded or laminated alluminium or copper fins. Thanks to our special assembly technology, thermal features and optimum mechanical resistance on the finish product is granted.

Copper base thickness and fins shape ( height, thickness, pitch) have been designed to meet every requirement.

Average dimensions of the copper base are starting from 9 mm thickness.

On the other hand pitch fins can start from 5 mm and thickness from 2 mm.

SuperFins can be assembled up to a maximum of 600 x 800 mm.

Thanks to their special design all SuperFins can be machined as any other extruded profiles with no problem at all: milling, drilling, screw thread, and so on.

Nomenclature

Herebelow some SuperFins thermal simulations carried out by FlotTerm.

As usual Pada Engineering R&D Dept. can suggest trough highly accurate thermal analysis the best possible optimized solution.